![]()

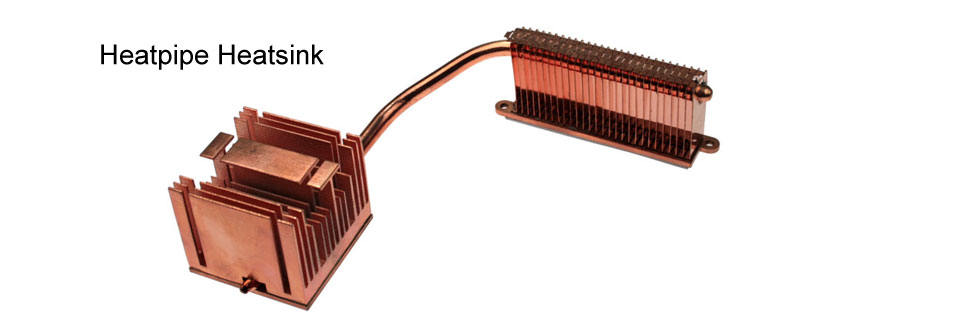

Heatpipe Heatsink

Heatpipe technology could be mentioned as a breakthrough compared to traditional cooling materials. It can provide high thermal conductivity under slight temperature difference.

Heatpipe consists of three parts: sealed hollow tube (normally copper pipe), the wick (or so called as capillary) and working fluid. For application, the part of heatpipe near to heat source is so called as Evaporation End, the end near to cold source (e.g. fins) and far from heat source is so called Condensation End

![]()

![]()

Heatpipe works in loops as follows:

- Even very low temperature difference can have the working fluid at Evaporation End turn into vapor.

- As the evaporating fluid fills in the wick, it spreads alongside the heat pipe towards the Condensation End.

- For the temperature even slightly below that of the Evaporation End, it occurs the condensation of the vapor.

- As it condenses, the vapor gives up the heat it acquired during evaporation.

- Then, the condensed working fluid is sucked back to the Evaporation End along the wick structure.

![]()

![]()

Heatpipe Type

From the type of wick structure, heatpipe could be divided into mainly three types. Groove structure, mesh structure and sintered structure. Sintered powder heatpipe enjoys much advantage in anti-gravity than that of groove type heatpipe or mesh type heatpipe.

From the way how heatpipe and fins are connected, heatsinks can be divided into two types, namely, stacked fins and soldered fins (or so called as zippered fin). The former one is to stamp the fins directly onto heatpipe w/o using any thermal interface material, certainly, there should be clearance between heatpipe diameter and the punched hole on fins. The latter one is to use solder paste to solder zippered fins onto heatpipe

![]()